In whatever shape and size the Airsoft pistols come in, they all need a bit of TLC on a regular basis. That’s the only way they can stay in tip-top running condition. So, it’s quite crucial that you understand how to properly maintain your piece.

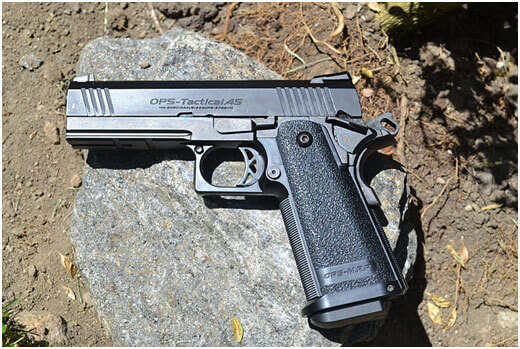

Figure 1: A Tokyo Marui Hi-Capa 4.3 Gas Blowback Airsoft Handgun

Source: Dwt110, Tokyo-marui-4.3-airsoft, CC BY 3.0

To that effect, you are going to learn how to take care of three popular types of Airsoft Gas handguns; a CO2 powered revolver , a Gas Non-Blowback Semi-Automatic and a Gas Blowback Semi-Automatic. Some of the guns that we referred to in this troubleshooting review are; the Wingun 7 Series CO2revolver, SOCOM Gear Gemtech Oasis plus the VFC Smith & Weson M&P 9C. Let’s get right to it then!

Note: Some troubleshooting steps may require disassembly. Disassembling your airsoft gun may void the warranty! Please check with the manufacturer's support team if you are unsure!

Where to Oil Your Gun

Before we even get to the cleaning and oiling, you have to first know that there three different types of surfaces that require regular lubrication. They are:

- Airseal surfaces which create air pressure, for instance the piston cup in the floating valve and the air nozzle

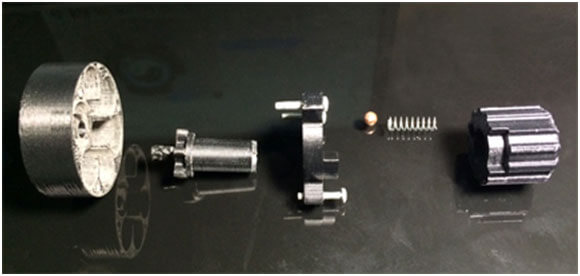

- Mechanical surfaces such as bushings/bearings, gears as well as other parts of the trigger and hammer

Source: Airsoft BBs Bearing by Lamune is licensed under the Creative Commons - Attribution license.

- Sliding surfaces, which suffer a lot of damage as well when neglected. They include the guide rod, the barrel, recoil spring the upper frame surface and the track that the frame moves against in the slide.

Cleaning, Oiling & General Troubleshooting

Tech Notes

OBJECTIVE: Cleaning and maintenance of your Airsoft Gas sidearm

DIFFICULTY LEVEL: 4 (out of 10)

TIME ESTIMATE: 20 minutes

TOOLS OF TRADE:

- Toothbrush

- Paper towels/rags

- Water

- Mild Soap

- White lithium grease

- Silicone lubricant

REPLACEMENT PARTS REQUIRED: N/A

STEP A: The first and probably the most important step in the maintenance of almost all types of pistols is proper magazine removal and disassembly of the gun. You must follow the exact instructions that are laid out for your particular model. For the VFC Smith & Weson M&P 9C, just drop the mag then pull back the slide. Switch the dismantling lever and then slide off the gun’s frame.

STEP B: Before starting the relubrication process of your gun, ensure that there is no excessive build-up of lube or any form of dirt and debris on the slide and frame. If you have been spending a lot of time playing in dusty spaces, then you’ll obviously be doing a lot of dirt and dust cleaning. Use the rags, paper towels and a toothbrush for cleaning up the small areas.

STEP C: Once you are done with the cleaning, you can now begin the lubrication process. Apply the appropriate lubricant to the frame and the slide. I recommend using the white lithium grease in the frame. Apply it to the striker/hammer assembly and the rails as well. Make sure that none of the grease gets in contact with the components that are made of rubber.

STEP D:To ensure that everything slides with effortless smoothness together, apply a bit of the white lithium grease on the inner rails inside the slide. For the blowback assembly, apply a couple of pure silicone lubricant drops to the blowback chamber rails and the inner piston.

STEP E: Your inner barrel and hop-up backing also have to be kept clean and free of lubricant and dirt just like your primary. So, after you disassemble the hop-up unit, remove the hop-up bucking and the barrel and thoroughly clean them out. Use some mild soap and tepid water to clean the bucking. Don’t forget to dry it properly after you are done with the cleaning.

STEP F: To make sure that your barrel is accurate (and happy), you just have to clean it completely. So, attach a clean piece of paper towel or a patch to a cleaning rod and run it down the barrel. Run the pieces of paper towel/patches through till they come out completely spotless.

STEP G: Once you complete the cleaning and lubrication process, you can now start the re-assembly while ensuring proper functioning, especially in the smooth slide operation.

STEP H: Just like the rest of your gun, the airsoft gas blowback magazine also needs a bit of care and maintenance, particularly if you’re using propane and not Green Gas (pre-lubricated). For propane, you should add two drops of the silicone lubricant for every 3 or 4 magazine fills. That’s the best way to guarantee that they are internally lubricated. On the external side, you should also ensure that you sufficiently lubricate the rubber seal at the top using silicone.

STEP I:In case you have an NBB (non-blowback pistol), you can follow the same steps but with just a few tweaks. Since there aren’t any blowback assemblies or frame rails that are supposed to be cleaned up and lubricated, the NBB replicas have a much simpler maintenance routine. For the SOCOM Gear Gemtech Oasis on the other hand, the only parts that I’ve ever had to lubricate are the magazine using silicone lubricant and the trigger mechanism using white lithium grease.

STEP J:In some cases, the inner O-ring of some gun magazines M4 High Capacity Magazine could dry out leading to leakage of the fill valve. Luckily, you can easily rectify this by undoing the fill valve with a flat-head screwdriver. After unscrewing it, place it in a tiny cup and for a few hours, soak it in silicone lubricant.

STEP K: Just like actual handguns, Airsoft revolvers also need much less maintenance as compared to their NBB or GBB(gas-blowback) counterparts. Essentially, when it comes to the Wingun 7 Series CO2revolver, the only maintenance stuff that I’ve ever carried out is ensuring that I’ve cleaned up and nicely lubricated the cylinder lugs including speed loaders(if you have them) using a few white lithium grease drops.

Source: Another Airsoft speed loader by Archrival is licensed under the Creative Commons - Attribution - Non-Commercial license.

STEP L: Four a touch of extra efficiency to the gas port in the chamber meeting up with the shells, you should add a few drops of silicone lubricant to the chamber’s gas port where it comes into contact with the shells. However, you don’t have to add the silicone lube to the interior parts of this Wingun 7 Series CO2 revolver since CO2 is a dry gas and the interior parts of this revolver are intended to run dry. Check out spare shells for UHC revolvers.

More on Gas Blowback Pistols

Today,we’re focusing a lot on the gas blowback pistols (GBB) largely because they are the most popular among all the above-mentioned types. In fact, the GBB types are perhaps the most functionally realistic pieces of kit in your loadout collection. As exciting as it is, your GBB is usually one of the most misunderstood loadout gear as well. Luckily, you are going to learn the importance of maintaining your piece and how to do it properly. Learn more about the basic controls of a gas blowback pistol.

The Mechanics of a GBB Pistol

One of the best things about the GBB is that it not only looks like an actual pistol but its feel and handling is also quite similar to the real thing. These types of pistols fundamentally function by use of compressed gas which blows a pellet out through the barrel. From the residual air pressure, the Floating Valve is inflated and moves the slide for a pellet reload mechanism and resetting the hammer.

Common Practice

As already mentioned, controlling a gas-blowback pistol such as the Elite Force 1911 is usually identical or nearly identical to a real pistol. Therefore, you must understand how your gun works so that you can be effective and uphold safety while using it in the field. Some of the main points to be grasped are:

- In the first round, the slide has to be actuated to the chamber.

- You can prevent accidental/unwanted discharge if your gun has a de-cocker

- Choose your holster carefully to prevent loss of a magazine in the field since the mag release may be in one of a few different places.

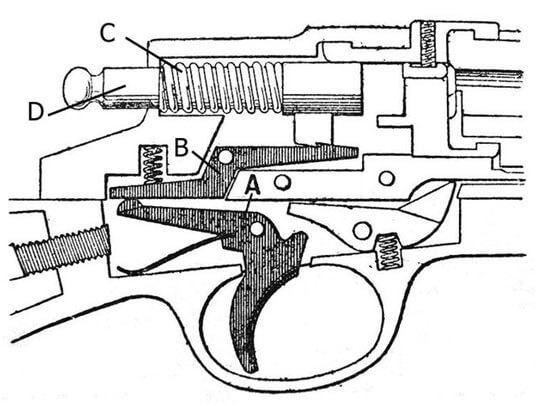

- You may operate the trigger in single-action or double-action

- Single-action: Here, prior to shooting, you are supposed to arm the hammer by pulling it (the hammer) back or racking the slide. If a de-cocker is included in your model, the chamber can safely carry a live round without the risk of accidental firing. However, you will still need to pull back the hammer if you want to shoot.

- Double-action: Here, you should also chamber your round before firing and whenever you pull the trigger, the hammer will move. Since a de-cocker is not usually available, you have to keep it in ‘safe mode’ out of combat zones.

Source: Unknown (Collective work)[Public domain], via Wikimedia Commons

What Not to Do

There are a number of things that you should never do if you want to prevent your gun from wearing out or breaking down quickly. They include:

- Avoid dry-firing your pistol since it leads to fast slide-lock wear and has immense potential of damaging the floating valve parts that are made of rubber.

- If the gun doesn’t have any ammo, avoid clicking the trigger otherwise, the gas in the gun will wear the trigger spring out and consequently, wear the hammer out as well.That’s because the slide release tends to rub on the bottom of the slide if it (the slide) is pulled with no round in the mag.

- Do not scrap or sand down parts of the gun for any reason whatsoever, especially the barrel. This leads to severe clearance changes and as a result. drastic inaccuracy and loss of gas efficiency. Moreover, the slide release and safety interrupter may also be damaged in the process.

- If you fail/forget to properly oil your pistols as we’ve discussed above, the chances of jamming or breakdown are increased tenfold!

- Never leave green gas containers or charged Airsoft pistol mags in direct sunlight because they can EXPLODE!

Note: In a lot of guns, for instance the M9/92F patter pistols, the trigger spring is usually the weakest component of the gun. So, it comes as no surprise they are the quickest parts to wear out, even in most GBB pistols. To prevent premature failure, ensure that you avoid unnecessarily firing guns with unloaded pellets even if you want to ‘safely’ discharge them indoors. Generally, during normal operation, firing an unloaded gun may occur but the slide lock is usually disengaged during the firing process, till the last round is chambered and it then springs up. However, players in combat hardly get that far!

Common Problems of GBBs &Their Solutions

- My gun fails to shoot the entire magazine or it

Possible Issue i: Your gas bottle is too empty

Solution: Confirm that your gas bottle is adequately filled, if not, fill it up.

Solution: Confirm that you properly fill the magazine. Ensure that you hold the canister of gas propane perpendicularly upside down then press it downwards for about 5 seconds (depending on your model) to fill the magazines.

Possible Issue iii: The temperature may be too low to generate enough pressure for firing off the entire magazine.

Solution: Airsoft guns usually fail to work properly in temperatures under 450F. Rapid firing of several magazines back to back may also chill the internal parts of your Airsoft pistol below the 450F thereby resulting to cold related malfunctions and misfires even on a 900F day! Warm up the gun and you’re good to go!

- My gun just blew out a cloud of gas via the ejecting port.

Possible Issue i: Your magazine pressure was only enough for partially resetting the slide and thus locked the hammer down nearly halfway through thus making gas to blow out of the ejection port into the air.

Solution: Switch to a fresh bottle of gas or warm up your gun a little.

Since this problem is also a gas pressure issue, you can also refer to the possible issues and recommended solutions to problem one above for comprehensive fix.

- My slide isn’t locking back after I fire the last pellet.

Possible Issue i: The slide isn’t locking back since it isn’t hitting the mechanical stop that’s in the rear. This could happen if your upgraded your recoil spring and it becomes too heavy.

Solution: Consider changing your recoil spring back

Possible Issue ii: Your slide lock is partially worn out

Solution: Replace your slide lock with a new one.

In case your slide lock isn’t worn out and you did not upgrade the recoil spring, refer to the possible issues to problem one (1) above and carry out the recommended solutions since this could be a low-pressure issue.

- My gun doesn’t have range

Possible Issue i: Your fixed hop up may be designed for a pellet that’s much lighter than what you are currently using.

Solution: Switch to lighter pellets

If switching to lighter pellets doesn’t solve your problem, this may be a gas pressure problem as well. In that case, refer to the possible issues and solutions to problem 1 above for a complete troubleshooting exercise.Mind you, your gun may also simply have a low range!

Quick Tips

Unlike AEGs, gas pistols usually chew through grease and oil quite fast particularly when you’re in action. Furthermore, their parts are much more exposed and more susceptible to contamination in contrast their AEG counterparts whose mechanical bits are completely enclosed.

So, for the highest level of efficiency whenever you use your gun, here are some quick tips to follow.

- You should make it a habit to always field-strip your it to check the oil after every 6 hours you spend with the gun strapped to your side.

- Ideally, clean and oil your pistol once before going to action and once after you complete every game.

- In case you are playing in Realms of Ruin or equally sandy areas, increase the frequency of cleaning and oiling your gun

- If you are going on a 24-hour game, I recommend that you clean it up and re-oil it after you complete every segment of the game.

- To save gas and avoid expensive costs in repair that may result from over-charging your Airsoft gun mags, you should take some time to study the amount of gas charge in seconds, your mag needs to fire only the maximum BBs/pellets that can be loaded at a time.

- Again, oiling the O-rings and valves before prolonged storage prevents drying out shrinking or cracking.

- GBBs tend to vibrate quite hard with every shot that’s fired, check and tighten the screws around the striker/hammer assembly on a regular basis.

- Before storage, leave a very small charge of gas in your magazine to help retain back pressure on the O-rings and valves.

- When you plan to store your gun for prolonged periods, ensure that you remove all but one pellet from the magazine. That way, you will prevent the spring of the magazine from permanent compression and losing sufficient tension that is required for proper loading of the pellets.

Final Words

So, it’s as simple as that. In just a quick couple of minutes, you can keep your Airsoft pistols operating in optimal shooting condition for years and years, barely using any tools. A lot of players neglect maintaining their Airsoft pistol and unfortunately, it usually results to decreased performance or failure. Spare a few minutes of your time out of your day to carry out these easy tricks and you’ll easily prevent any inefficiencies or breakdowns when using your sidearm in the field!